Use Real Lean as your first step to release capacity

Faced with a need to increase laboratory testing capacity, Real Lean releases hidden capacity quickly and cost effectively.

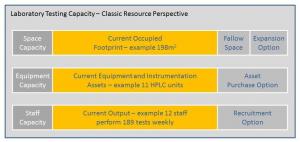

Increased demand for lab capacity is a positive indicator of a growing business. Deciding upon the best option to increase capacity, however, never seems to be easy! In particular, when existing space, equipment and staffing capacity is thought to be maxed out, the next option tends to involve a space expansion (see the top row of graphic below) – a complex project with significant capital expenditure, which drags stakeholders from Engineering and Facilities, Finance and HR into the mix.

Once available space is fully exploited, the next option often exercised when faced with test output demand increases is to purchase, install and commission new instrumentation and equipment.

This often finally requires the recruitment of additional staff.

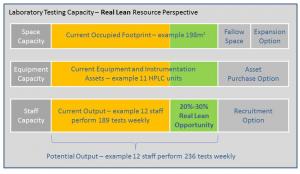

Take a look at the graphic below. In most labs there is a 20% to 30% “Real Lean” opportunity to release capacity from existing staff, equipment and space. This capacity is tied up in failing to deal effectively with volatile workloads. It can be released through well-designed solutions which level workloads, flow sample testing through defined sequences and visualise analyst tasks with the help of standard roles.

If we could increase testing capacity by 20%-30%, without capital expenditure or investment in recruitment and training, in a 6-month transformation project (rather than a two-year expansion project), would we be interested in knowing more about that option?

Big Pharma now partners with BSM to do just this – releasing the latent capacity locked in assets they already own and employ.

Our consultants can provide further information on the above and discuss any aspect of Real Lean Transformation, simply set-up a call today.