BSM's approach to applying Lean in Laboratories is based on the following key concepts:

- The Impact of Volatile Workloads

- Achieving Levelling and Flow in Labs

- Realising the Benefits of Lean Lab (Speed or Productivity)

1. The Impact of Volatile Workloads

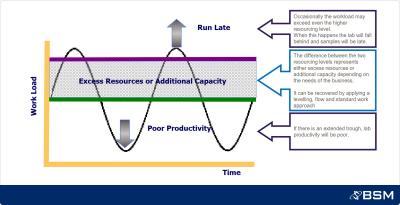

When incoming workload exceeds capacity, a lab will fall behind and samples will be late. Because it is usually considered worse to be late than expensive, labs with volatile workloads often carry more resources than required to process the mean workload.

However, even with some excess resources, they still fall behind during the highest peaks and conversely suffer from poor productivity during extended periods of low incoming workload.

The difference between the staffing required for the mean workload and the actual staffing level represents additional capacity and is recoverable if you can level the workload.

2. Achieving Levelling and Flow in Labs

Short term volatility (in overall workload and in the mix of samples) is by far the biggest lean opportunity in most labs. Successfully levelling a volatile workload will deliver significantly greater benefits than waste elimination alone.

However because the relationship between volatility and flow is not intuitive and often not well understood, flow is simply ignored in many lean lab projects. ‘Waste’ by comparison is easy to see and understand and many weaker lean projects are based solely on waste reduction and/or 5S. Levelling a volatile workload will typically generate improvements in productivity of between 20 and 80%.

BSM works with clients to level workloads and create flow in their labs. We do this by developing repeating sequences of testing that move the samples through all required tests and reviews quickly (at the levelled demand rate). Once started, samples do not queue between tests and this significantly reduces the ‘through-put’ time. The difference between the reduced ‘through-put’ time and the lead time is used to allow samples to be held in an incoming queue until they can be released into the lab as part of a levelled daily or weekly workload.

3. Realising the Benefits of Lean - Speed or Productivity

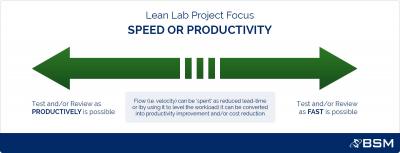

Improved flow (velocity) can be directly converted into lead time reduction or by using it to allow samples to wait in a 'levelling queue', it can be used to reduce volatility. Reduced volatility can then be converted into additional capacity or a cost reduction.

Lean improves flow and reduces waste. When incoming workloads are volatile, a lab generally has to choose between using these benefits to reduce lead times, or alternatively to become more productive.

BSM’s view is that each lab should aim to be as productive as possible within the lead time of the overall value stream constraint.

The overall value stream constraint is that part of the end to end process with the longest lead time. For example in a 'batch release' process, the overall constraint may be in another lab which has a longer minimum 'through-put' time (e.g. sterility testing) or it may be outside of the labs altogether (e.g. in the batch record approval process).

There is no net advantage to the business in an individual lab being faster than the slowest part of the overall process.