Active Pharmaceutical Ingredient (API)

Objectives

Reduce the overall lead time from manufacture of the product to final release (Quality Control and Quality Assurance).

Solutions Deployed

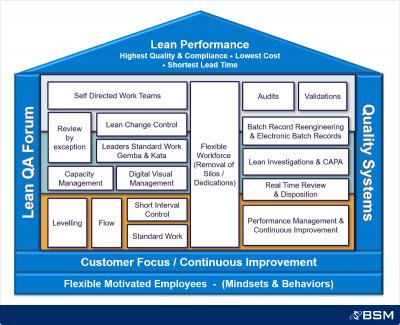

Quality Control: queue based levelling and rhythm wheel, standard work roles, visual management.

Quality Assurance: batch record re-engineering, process optimization (batch record review and corrections, investigation management, disposition).

Results

- Reduction in QC lead time from an average of 13.4 days to an average of 4.7 days

- Alignment of the QA timeline to the QC timeline i.e. disposition ready to complete as soon as the lab results are finalized

- Fixed repeatable analyst requirement

- Continuous improvement culture and mind-set growing within the laboratories