Improving Right First Time (RFT), by creating a simpler and more user friendly batch record.

Objectives

Our client, a Quality Assurance (QA) organization, had recently initiated a program to improve batch record format and layout. The ultimate aim of this initiative was to increase Right First Time (RFT), review lead-time performance and productivity by creating a simpler and more user friendly batch record.

Solutions Deployed

- Mapping of the manufacturing process with all relevant groups. This included process engineers, manufacturing QA, OPS and disposition QA.

- Mapping batch record life cycle with all relevant groups, including tech services, batch record issuance, QA and document control.

- Analysis of investigations where the root cause was a ‘failure to follow’ batch record instructions.

- Categorization of entries in the batch record and identification of common sources of error.

- Workshops with all user groups to challenge entries with the aim to reduce or simplify.

- Data masking and shading to error proof document.

- Combinations of classroom training and media fill dry runs.

- Tracker to capture and trend documentation errors.

Results

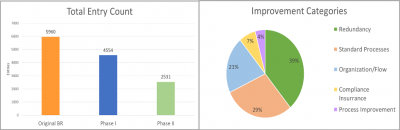

- Reduced page count by 62% (370 to 139 pages)

- Reduced entry count by 58%

- Reduction in transcription entries of 77%

- Improved organization and flow

- Improved compliance

- Reduction in time taken to compile record

- Improved RFT performance

- Reduction in throughput time for QA review