Pharmaceutical Packaging Operation

Objectives

-

Improve delivery performance (OTIF) to customer base

-

Optimise capacity & productivity in the packing operation

-

Provide improved visibility of upcoming workload for support functions such as QC & QA

-

Re-engineer the planning process

Solutions Deployed

-

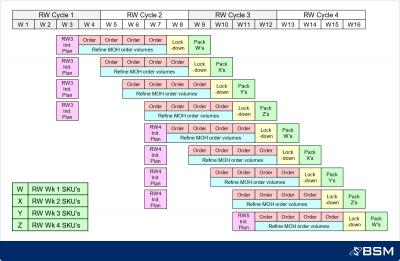

A ‘Rhythm Wheel’ based scheduling process for packaging operations

-

Re-designed planning processes - via RACI, SIPOC, flowcharts, meeting agenda’s & Planner Standard Work

-

Clearly defined lead time targets & KPI’s for all relevant functions

Results

-

Increased packing capacity & productivity of 10% - 20%, via a reduction in line clearance frequency & complexity

-

Improved delivery performance (OTIF) of ~30%

-

Standardised planning process for scheduling of packing operations

-

Improved visibility of upcoming workload